This report was transcribed from the original located in the U.K. Archives at Kew. It was provided to the U-boat Archive by U.K. researcher Roger Griffiths. |

COPY No. |

|||

|

|||

C.B. 4318 |

|||

R |

|||

REPORT |

|||

ON |

|||

"U-570" |

|||

(H.M.S. "GRAPH") |

|||

1943 |

|||

Attention is drawn to the penalties attaching to any infraction of the Official Secrets Acts. |

||

C.B. 4318 |

||

R |

||

REPORT |

||

ON |

||

"U-570" |

||

(H.M.S. "GRAPH") |

||

1943 |

||

| INTELLIGENCE DIVISION | ||

| NAVAL STAFF, | ||

ADMIRALTY. |

||

January, 1943. |

||

| (M.O.6073/42.) | ||

2 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CONTENTS |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PLATES |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3 |

||

CHAPTER I |

||

EARLY HISTORY AND CAPTURE |

||

"Graph," ex "U 570," is a 500-ton U-Boat, Type VIIC, and was built at the Blohm & Voss Yards, Hamburg. Commissioned on 15th May, 1941, with a crew consisting of 4 officers, 3 chief petty officers, 11 petty officers and 25 men, she carried out trials, mainly from Kiel and Horton, on Oslo Fjord, until about 23rd July, when, during a crash dive from a suspected British aircraft, she struck a reef and damaged her bows. At the end of July, 1941, she was docked at Ytrre Havn for repairs and after further trials she was ready for her first patrol on 22nd August, 1941. |

||

2. On 24th August "U 570" left the fjord and proceeded mainly on the surface to an area south of Iceland. She dived twice for aircraft but breakdowns of machinery caused more trouble than did the attentions of her enemies. This unsatisfactory state of affairs was quickly reversed, however, at about 1050 on 27th August. "U 570" at this time was diving deep to get some respite from the heavy seas which had already caused much seasickness amongst her crew. Possibly in order to take a sight, her captain decided to surface and, neglecting the elementary precaution of ensuring it was safe to do so, came up almost immediately underneath a Hudson aircraft "S" belonging to 269 Squadron, piloted by Squadron Leader Thompson. "U 570" perceived her danger too late and, as she was diving, a stick of four 250 lb. depth-charges exploded close alongside her. The lights were put out and some gauge glasses fractured, and it was doubtless the sound of water pouring through these, added to the confusion caused by the blackness (the auxiliary lighting system having failed) and the panic of an inexperienced crew that caused the captain to order the boat to be brought to the surface and surrendered. |

||

3. As soon as the submarine surfaced the aircraft attacked with guns until about a dozen of the crew, who had emerged from the boat on to the bridge, waved a white flag. |

||

4. In a short while the entire crew had gathered on the bridge. The sea was too rough to sink their ship and take to a raft and they do not appear to have considered it politic to attempt to drive off the aircraft with their A.A. gun. Huddled in their miserable position the crew remained throughout the day. At 1345 the Hudson was relieved by a Catalina. As the day drew on a few members of the crew regained some measure of composure. The confidential books and papers and cypher machine were thrown overboard and the A.E.G. gear smashed. A wireless message was passed to the Vice-Admiral, U-Boats, stating their position. |

||

5. Later, some unskilled and unsuccessful attempts were made to repair the damage, but, at the approach of the trawler "Northern Chief" at 2250, all efforts were abandoned. H.M.S. "Burwell" arrived at 0550 and immediately received this signal from "U 570": "Will you take off our crew?" to which "Burwell" replied, "Blow main ballast tanks and send half your crew below." No reply was received and a further signal was made: "Do not attempt to throw any papers overboard and do not attempt to scuttle," which elicited the reply," What does scuttle mean?" Several unsuccessful attempts were then made by "Burwell" and "Windermere" to take "U 570" in tow. At 1030, after "U 570" had signalled many times, "Will you take off our crew, we are sinking," "Burwell" replied, "Blow all fuel overboard." |

||

6. No action was taken, nor did any of the crew go below. The submarine appeared to be settling deeper in the water, so the Commanding Officer, H.M.S. "Burwell," ordered a burst of machine-gun fire to be fired over the bridge. The gunner's aim was spoilt by the heavy seas and five of "U 570's" crew were wounded. Others rushed below and the main ballast and fuel tanks were blown, and the submarine for the first time since its capture appeared to be in a reasonable condition of buoyancy. |

||

7. At 1350, after more unsuccessful attempts to tow "U 570," she asked for her wounded to be removed. Two officers and ratings from the trawler "Kingston Agate" went alongside in a Carley raft, and were almost overwhelmed in the concerted rush made by the officers, who had to be forcibly persuaded back on board in order that the wounded might be removed first. |

||

8. It was not until 2100 hrs. that "U 570" was finally got in tow. Unfortunately, in the intervening period some of the trawlers had removed the entire crew which resulted in a loss of control over the submarine which nearly caused her total loss. As it was, since the submarine appeared to be slowly losing buoyancy, she had to be taken to the nearest land and was eventually beached at Thorlakshafn, about 24 hours later. It had been intended to beach her bows on and hold her in that position with appropriately located anchors. In fact, the submarine beached herself broadside on before this operation could be carried out. |

||

9. On 30th August, Lieutenant G.R. Colvin, Wt. Engineer Giordan, an E.R.A. and P.O. L.T.O. arrived by air at Reykjavik and proceeded the following day to Thorlakshafn, boarding the submarine through breaking surf at 1300. |

||

10. "U 570" was then lying broadside on to the surf and listing heavily to starboard (i.e. in shore). She was on a gently shelving beach of soft sand, completely open to the south-east, and had been driven well up the beach by a moderate swell. The interior of the submarine was unlit and in a chaotic state. Leaks of oil and water from broken gauge glasses of internal tanks had combined with vast quantities of provisions, flour, dried peas and beans, soft fruit, clothes and bedding, and the remains of scores of loaves of black bread to form a revolting morass that in places was knee deep. It was subsequently discovered that the crew's W.C. had been converted into a food locker and overturned buckets of excrement added to the general noisome conditions. |

||

(C50426) B2 |

||

4 |

||

11. The following damage had been done by the crew: |

||

(i) The engine room was flooded to the deck plates due to the removal of a strainer cover. This had been replaced by the crew themselves but not rendered completely watertight. |

||

(ii) A.E.G. gear completely smashed. |

||

(iii) W/T set damaged. |

||

(iv) Attack instrument dials smashed. |

||

(v) Anschutz compass dropped. |

||

(vi) Control room and conning tower deep diving gauges defaced. |

||

(vii) Forward periscope lowered into its well and the well filled with oil and water. |

||

12. The following damage was caused by depth charges: |

||

(i) 3-in. split in pressure hull on port side. |

||

(ii) 90 per cent. battery containers cracked. |

||

(iii) Bulkhead between both battery tanks and internal O.F. tanks slightly buckled. |

||

(iv) One of two pairs of 500-amp. fuse holders broken. This caused the loss of all lighting and power to auxiliaries. |

||

(v) Battery supply switches to the main motor switchboards jumped off but were undamaged. |

||

(vi) Several gauge glasses, lights, porcelain fuses and a few minor bracket welds broken. |

||

13. Between p.m. on Sunday, 31st August, and 0500, Friday, 5th September, the submarine was made seaworthy. This involved the restoration of lighting, the tracing of all air and water services throughout the boat, finding and shutting vents, Kingstons, bulkhead and tankside valves, blowing main ballast tanks with the little air remaining, pumping out the bilges with a small semi-rotary pump and clearing the ship of some of the fifth. |

||

14. At 0500 on Friday, 5th September, "U 570" was hauled off the beach by the salvage tug "Salvoina" and floated with a 3° list to starboard and slightly bow down. Main ballast was further blown by a portable L.P. air compressor brought alongside by a corvette, and at 1300 the passage to Hvalfjord commenced. |

||

15. The air in the submarine had now become almost unbreathable and Lieutenant Colvin and his party remained on the bridge in the extreme cold throughout the passage. The weather was favorable and the submarine arrived alongside H.M.S. "Hecla" at 0930 on Saturday, 6th September. |

||

16. The work of preparing the submarine for passage under her own power to Barrow-in-Furness now commenced, and by 25th September she was in all respects ready for Sea, her crew having joined four days earlier and sea trials having been carried out on the previous two days. |

||

17. At 1600 on 29th September, "U 570" left Iceland, escorted by H.M.S. "Saladin," arriving at Barrow at 0900 on 3rd October, having made good 13 knots for the majority of the passage. |

||

SHORT GENERAL DESCRIPTION |

||

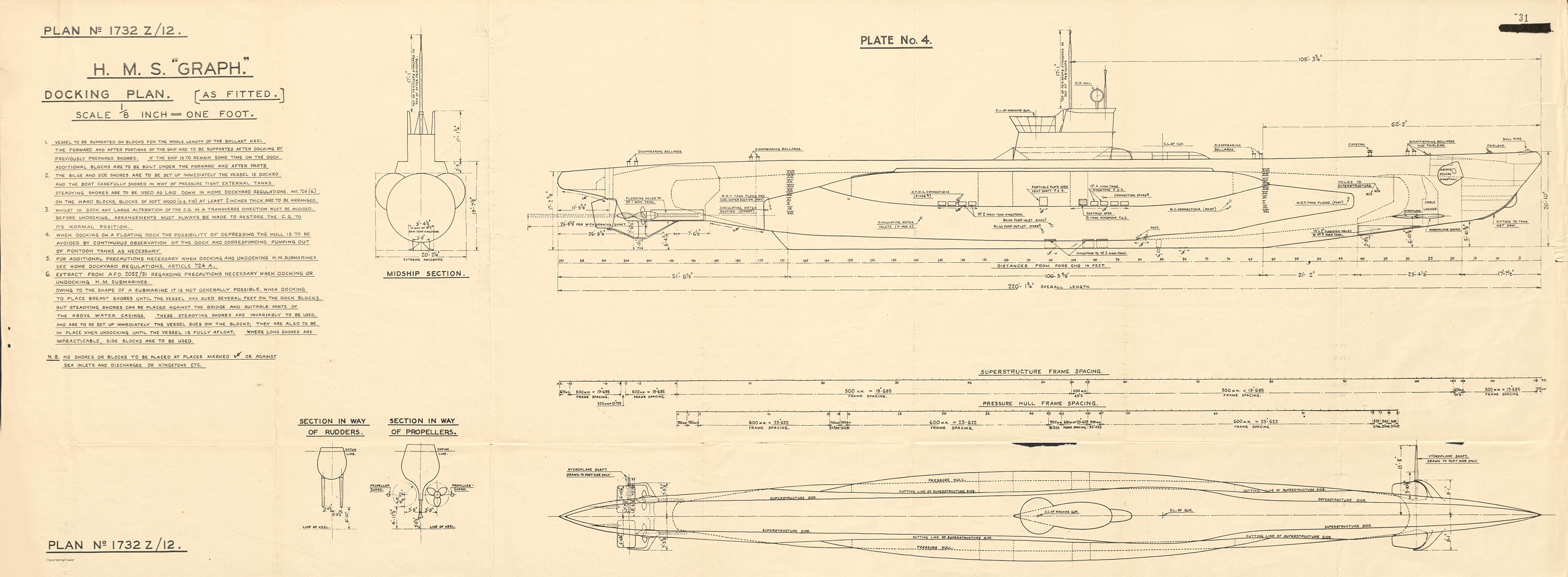

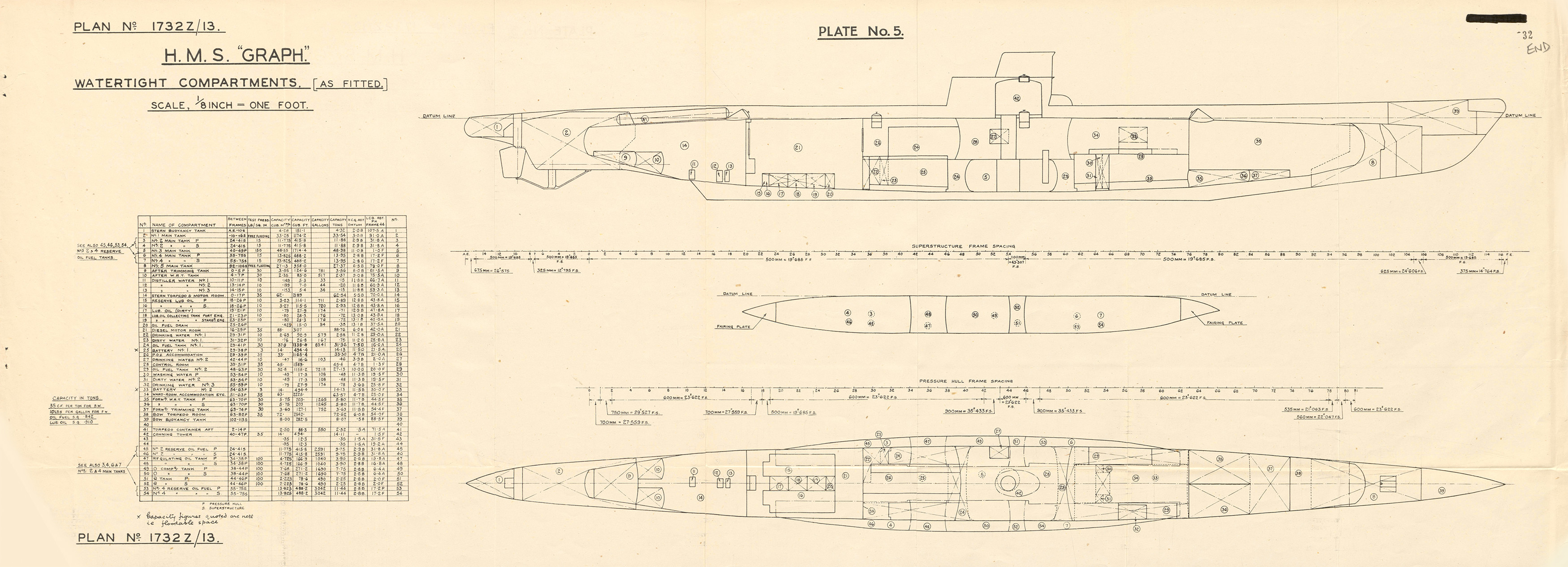

| "Graph," although nominally a 500-ton U-Boat, has a surface displacement of 784 tons, including approximately 42 tons of oil fuel in Nos. 2 and 4 external main ballast tanks, and a submerged displacement of 883 tons. Overall length is 220 ft. with a pressure hull diameter of 15.6 in. Her maximum surface speed is 18.8 knots. | ||

| 2. One hundred and nine tons of fuel are carried, about 55 per cent. inside the pressure hull and the remainder in external tanks which can also function as main ballast tanks. This gives the submarine a surface endurance of about 7,500 miles at 10 knots on both engines. | ||

| 3. Submerged speed is 8 knots and endurance is slightly less than for our own submarines. | ||

| 4. The pressure hull thickness is 0.88 in. amidships, decreasing to 0.63 towards the end. End dished bulkheads are 1.378 in. thick. Except for the cover plates over the engine room and the dished bulkheads at each end of the internal main ballast tanks where riveting is used, the pressure hull which is of circular section throughout, is welded. The greater part of the welding has the appearance of having been done in the shops. | ||

| 5. One large main ballast tank is within the pressure hull - an undesirable feature. Other main ballast is in external saddle tanks and at the ends of the submarine. When carrying full stowage of fuel (i.e., with fuel in the main ballast tanks) the reserve buoyancy is only 99 tons, which is small compared with British practice. | ||

| 6. A good bow form is made possible by having only four internal bow tubes. The forward hydroplanes are of the drowned type and not arranged to house; both forward and aft hydroplanes protrude further than in our submarines. Control of the submarine dived is good. Projecting hydroplanes, together with the light jumping wire, flimsy hydroplane guards and flimsy spur to protect the rudder and screws when bottoming indicates that passage through anti-submarine nets is not regarded as important. | ||

| 7. Vents bow caps and torpedo transport are all hand worked. Many fittings standard in British submarines, such as drop keel, gun access trunk, L/P blowers, wireless mast, torpedo derrick, traversing rails and hunting gears are omitted. Without these omissions hopeless congestion would arise. As it it, congestion is serious in the forward and after ends, and living quarters are very cramped. | ||

5 |

||

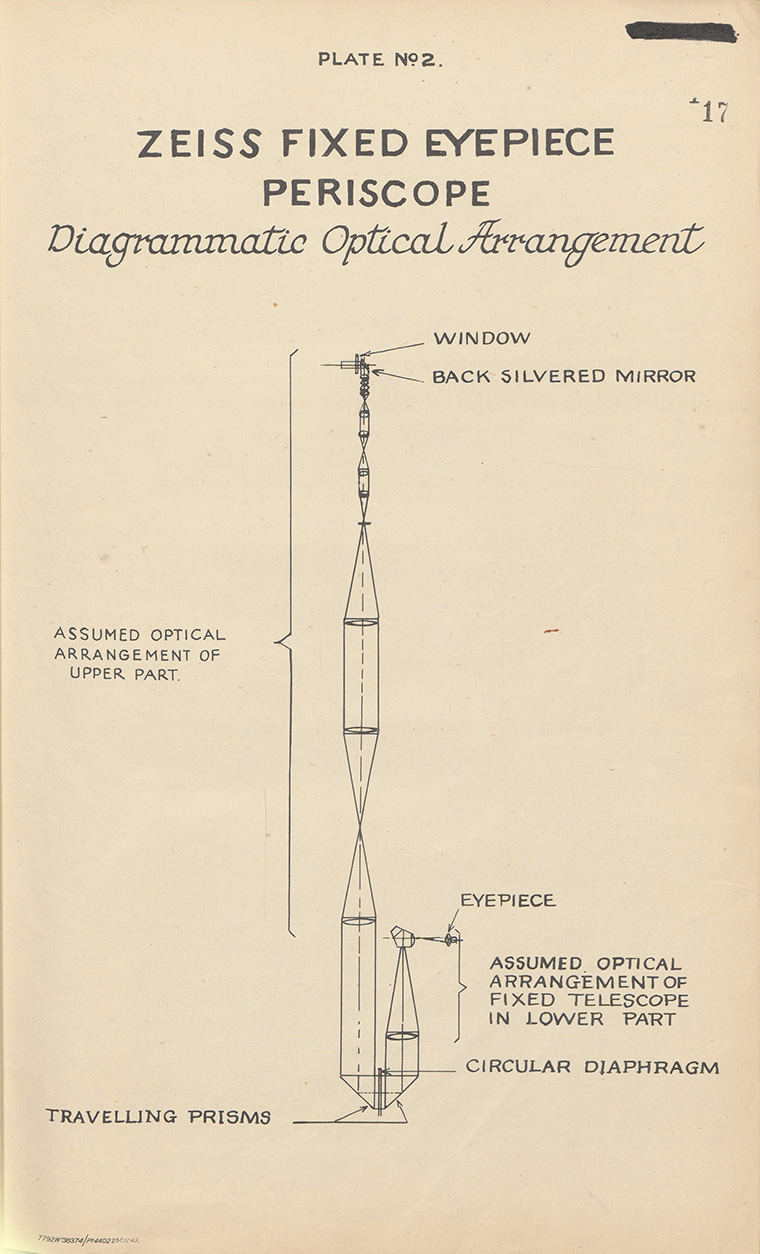

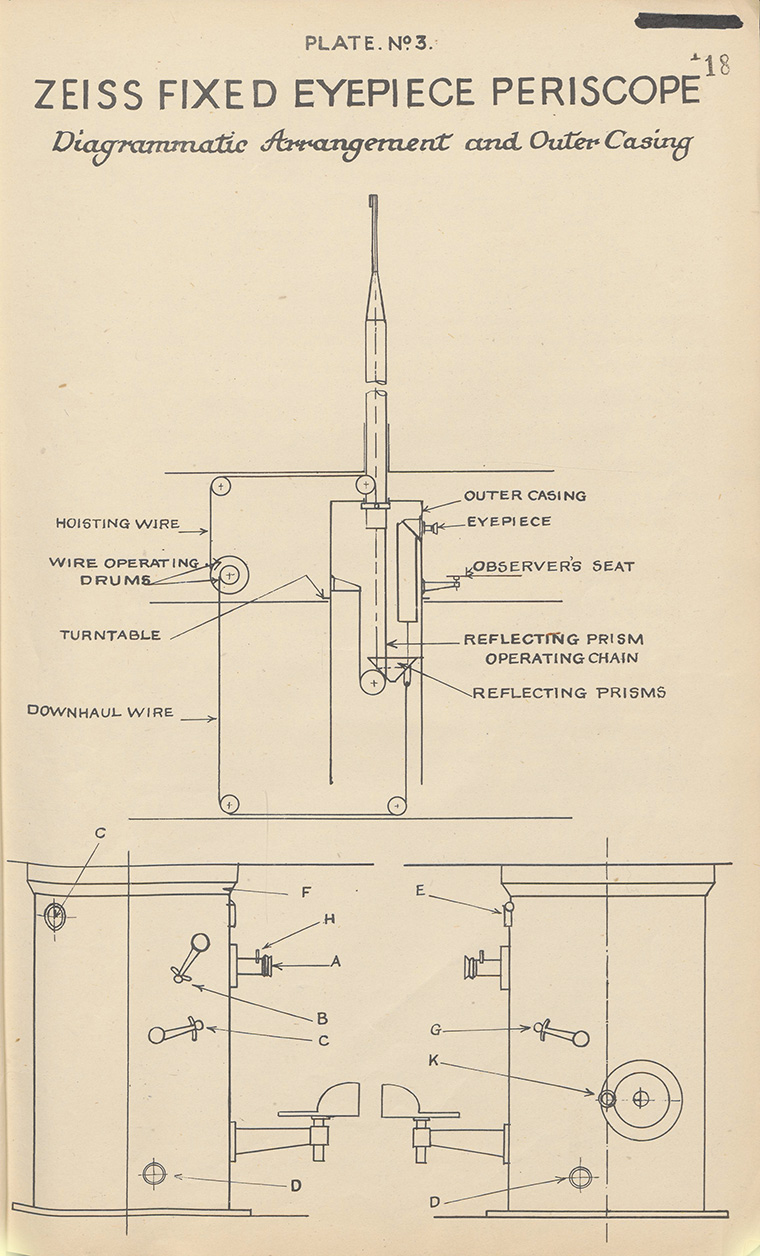

8. The fixed eyepiece periscope, operated from the conning tower, enables the silhouette to be kept very low. This, together with a low reserve buoyancy, when carrying oil fuel in main ballast tanks, makes the bridge extremely wet in short seas. Experience has proved, however, that though she rides comfortably in a heavy swell, speed has to be considerably reduced. |

||

9. Kingstons and vents are large compared with ours. The internal main ballast tank is fitted with two large hand-worked vents, two intermediate vents and six large, square kingstons. The latter open outwards and are protected by a plate protruding from the pressure hull. |

||

10. Twin rudders are fitted aft. This is necessitated by the central (internal) torpedo tube aft. This double rudder does not give a better turning radius than in "S" class submarines. |

||

11. The battery ventilation is by means of the "separate cell ventilation system." |

||

12. The engine room hatch is fitted as an escape hatch. |

||

13. A small refrigerator, combined with little stowage for food and a small galley, reduce living conditions below the British standard. |

||

Engineering |

||

14. The engines are as large as can possibly be fitted in the available space with a fairly low shaft centre line. The four-stroke engines are of 15.75 in. bore and 18.1 in. stroke, 6 cylinder, reversible, with engine-driven positive displacement superchargers. The latter are driven through double cone clutches. |

||

15. Double cone engine and tail clutches are fitted. |

||

16. Auxiliaries are generally electrically or air operated. |

||

Electrical |

||

17. The general principles of the electrical installation are similar to those adopted in our modern submarines. A main battery in two sections (62 cells in both sections) provides the power and tandem main motors on each shaft provide for submerged drive. |

||

18. Both batteries and motors can be grouped in series or parallel. The control gear for varying these groups and for starting and reversing the main motors is semi-automatic and is so designated that comparatively little training of the operators is required. |

||

19. The auxiliary electric circuits are fed by a double tree system from auxiliary switchboards situated at the main switchboard and in the control room. Such a system is used in small British surface ships, but not in submarines, where a ring main is preferred. |

||

20. The submarine did not appear to have been "wiped" or "flashed" but may have been "depermed." |

||

Armament |

||

21. Torpedo armament comprises four bow and one stern torpedo tube. |

||

22. Seven re-loads are carried internally and two externally, making a total of 14 torpedoes. |

||

| 23. Torpedo tubes and fittings are of excellent finish and the gear connected with them is readily accessible. Gyro angling gear is more complicated than ours but permits application of very accurate angling up to the last moment of the attack. | ||

| 24. Firing gear is similar to ours, but the torpedo is ejected from the tube by a ram which gives certain splashless discharge. | ||

| 25. The bow cap is very similar to our design. Embarkation and loading of torpedoes is by hand with an overhead rail. | ||

| 26. "Graph" had no mines aboard but it would seem she could carry up to 36 mines. | ||

| Gunnery | ||

| 27. "Graph" mounts: | ||

| (a) One 88 mm. gun on deck before the conning tower, giving maximum range of 13,000 yards. Outfit of ammunition about 150 rounds. | ||

| (b) One 20 mm. Solothurn type A.A/L.A. gun on the after end of the bridge. Outfit of ammunition for this gun is not known. | ||

| (c) An unknown number of 7.92 mm. machine guns. None was found on board, though it is known they were carried. | ||

| Acoustic Apparatus | ||

| 28. The outstanding feature is the number and complication of the acoustic equipment. There are over 70 hydrophones and oscillator units fitted in the hull. | ||

| W/T Equipment | ||

| 29. This is similar but of lower power than in British submarines. | ||

| Conclusion | ||

On the whole, it may be said that "Graph" was built - and well built - for the sole purpose of offensive action in war. In addition, the centralization of most controls and the number of automatic and semi-automatic fittings make it obvious that she has been designed to be run by an inexperienced crew with the minimum of experienced ratings. She was not captured through any serious defect of material, but as a result of being poorly manned. |

||

| (C504426) B3 | ||

6 |

||

CHAPTER I I |

||

ELECTRICS |

||

Main Motor Switchboards |

||

1. The starting arrangements consist of inserting a resistance in series with the tandem armatures; this resistance is short-circuited by means of a contactor and current relay as soon as the current has fallen to a predetermined value. |

||

2. The field switch on each motor is automatically closed on the closing of the main motor circuit breakers. |

||

3. The automatic features make it easier for an unskilled crew to operate the board, but definitely increases maintenance and the possibility of faults. |

||

4. All automatic switches can be operated by hand if necessary. |

||

5. The switchboards are of the enclosed type and very little of the operation can be seen without removing the covers. |

||

6. The boards are open for inspection at the back and connections are quite easy to get at; the exception is the main motor field regulators, which are enclosed. |

||

7. The non-automatic switches are as follows: Ahead astern switch, motor series parallel switch, battery series parallel switch. These switches are fitted with flipper blades and the motor circuit can be broken or made on all of them. |

||

8. Special attention has been given to sound insulate the above switches and their flipper blade with a resilient rubber. |

||

9. The field regulator is wound on porcelain formers and, while the whole gear is very robust, it is not certain how it would stand up to severe shock. |

||

10. All connections are of copper and of massive construction. |

||

11. The arc shields on the main motor contactor consist of two-ply syndanyo with an additional layer of bakelite on the outside. The layers are compressed and the material is very strong. |

||

Main Motors |

||

The main electric drive consists of two tandem armature sets of 465 kw. each. The armatures can be grouped in parallel or series and the batteries in parallel or series to give the desired speed range. |

||

The tandem fields can be grouped in parallel or series as required. |

||

The general design and construction is more or less in accordance with our own motors; the following points are, however, of interest: |

||

(i) The main yoke can be rotated by a worm on the outside of the main motor yoke casting (i.e., the external yoke is a fixture). |

||

| (ii) The yokes are of steel and the end brackets and cover plates of aluminium alloy. Very little attempt appears to have been made to shockproof the machines. | ||

| (iii) Each tandem set has four holding-down lugs, each lug is held down by two bolts and located by one dowel. | ||

| (iv) The aft port main motor can be used to give six volts for sick-cell charging, by alteration of the field system. | ||

| (v) Each armature can be used separately in the event of failure of the other. | ||

| (vi) The main motors are very silent in operation but the chain-driven speed indicator is noisy. | ||

| (vii) Main Motor Cooling System. Fan blows air into centre of machine and exhausts into trunking at each end, the trunking leads into water coolers between tandem sets, the air is then exhausted into atmosphere. | ||

| The fan motors are on resilient mountings and are connected to run only when the main motors are running. | ||

| Auxiliary Motors | ||

| 1. The motors take their supply from the 110-170-volt V.P. boards either in the main motor room or the control room. In the event of failure of the supply from one board, the supply can be maintained to the motors from the other board by means of a change-over switch. | ||

| 2. In general the motors are of very solid construction and no lack of material or labour is evident in their make-up. | ||

| 3. The field and armature system are in accordance with our own design with the exception of the series starting coils, which are superimposed on the field coil system. | ||

| 4. Yokes are made of steel, and in the smaller machines the end brackets are made of cast aluminium alloy. The air compressor, ballast and trim pumps have cast iron or malleable iron end brackets, all fan cowls and cover plates are made of alloy. | ||

| 5. The air compressor motor and forward hydroplane and steering motors are horizontal machines, all the other large machines, e.g., ballast, trim and telemotors, are vertical machines. In no case are the yokes or end brackets split. | ||

7 |

||

6. All auxiliary motors are fitted with ball bearings. In some cases the method of lubrication appears to be very inefficient as grease can only be inserted by opening up the speed indicator plug. In other cases Stauffer boxes are used. |

||

7. The machines appear to withstand heavy starting currents without sparking and the commutators, with the exception of the two ventilating fans, are in very good condition. |

||

8. There is no definite auxiliary machinery space and the ballast, telepumps and cooling plant are in the aft end of the control room. The capstan is operated by compressed air and there is no D.H. plant or L.P. blower. |

||

9. The majority of auxiliary machines are mounted on resilient mountings; the main exceptions being the air compressor, ballast and trim pumps. The trim pumps can be dispensed with while dived by using L.P. air, but this is not possible with the ballast pump. |

||

10. The steering and hydroplanes are all electric drive, the steering motor is controlled by push buttons from the control room, conning tower, and bridge, and hydroplanes from control room only. Steering and hydroplanes can be operated by hand through shafting in the event of failure of the motor or supply. |

||

11. There is no field regulation for the ballast or trim pumps and the output of the pumps is controlled by opening and shutting the valves. |

||

12. There are two condensers fitted between the positive and negative brushes of nearly all motors. The centre point is earthed. It is believed that these are fitted to prevent wireless interference. There is also the possibility that they may prevent excessive sparking in starting up. |

||

Auxiliary Motor Starters and Controllers |

||

1. From a casual look it would appear that the starters are very much smaller than the corresponding British type of the same rating; on closer inspection, however, it is found that in addition to the starter there is a large double pole rotary switch and a 6-in. ammeter. This arrangement enables the equipment to be better spaced out over the available space on the hull, but entails a considerable amount of additional wiring. |

||

2. Three or four motors are wired back to a common change-over switch, so that the supply can be obtained from either V.P. board. |

||

3. All starters and switches are watertight and have packed glans. In order to make a continuous connection between the cable braid and the starters or switch case, a piece of wire is twisted round the braid inside the gland and clamped by a set screw on the gland. |

||

4. Small flexible leads are used extensively throughout the vessel for earthing purposes. |

||

5. In general, all starters, switches and ammeters are fixed on resilient rubber mountings. It is considered that these mountings are primarily intended as shock absorbers and secondly as sound insulating mountings. |

||

6. The motors in general are started by inserting an auxiliary series field coil in the armature circuit, as soon as the motor is under way, this coil is shorted out and the motor connected directly across the line. The two-step start is quite noticeable to the ear when the machine is started. |

||

7. Small machines are started by connecting straight to the line through a double pole rotary switch. |

||

8. All Controller and Starter covers are removable, hinges are not used. |

||

Auxiliary Switchboards |

||

1. There are two auxiliary switchboards; one in the main motor room and one in the control room and they can be connected either to the forward or after battery or both; the forward main supply is obtained from the forward battery through the battery circuit breaker (3,000 amp.); the alternative supply to this board is obtained from after battery through 430 amp. 500-volt fuses and vice versa. |

||

2. Each board is divided into two, one part supplies the V.P. machinery and the ammeter on the board reads up to 600 amps. The other part of the board supplies the C.P. circuits and the voltage is maintained at 110 volts + 4 volts by means of a Brown Boverie automatic voltage regulator and a resistance bank. The voltage regulator can also be hand operated. |

||

| 3. Siemens cartridge fuses are used throughout the vessel for power, heating and lighting, the smaller fuse holders for heating and lighting are made of porcelain, the larger fuse holders are made of black moulded compound, the only exceptions to this type of fuse are the 480 amp. battery fuses on the battery circuit breakers. | ||

| 4. There is a battery ampere hour meter for each battery in the main motor room. | ||

| Lighting and Heating | ||

| 1. The lighting supply comes from the C.P. board either in the control room or in the main motor room and is maintained at 110 volts + 4 volts by means of a Brown Boverie automatic regulator and resistance bank; it will be noted that this regulator cannot boost the output voltage to 110 volts if the input voltage has fallen below 110 volts. | ||

| 2. The heating supply is taken from the V.P. board either in the control room or main motor room and the voltage varies between 110 and 170 volts according to the state of the batteries. | ||

| (C50426) B4 | ||

8 |

||||||||

3. The radiators are wound to suit the variable voltage. |

||||||||

4. The vessel is well lit and provided with well glass fittings; the glass may be toughened glass, no well glass lights were broken by the explosion of the bombs during action. |

||||||||

5. All wiring, fittings, fuze boxes, distribution boxes, for heating and lighting circuits are watertight. |

||||||||

6. There are several portable lamps and radiators with flexible leads which plug into watertight sockets. |

||||||||

7. There is an emergency lighting supply by battery in each compartment in case the main lighting supply should fail. This battery supply is connected by a relay with the lighting circuit so that in the event of failure the battery is automatically connected to a small wattage lamp. It is believed that the batteries were dry cells but as they had been removed from the boxes it is not possible to be certain. |

||||||||

8. The fuse and distribution boxes are of the quick close and open type and are made of aluminium alloy, the quick close handle is made of steel, the boxes are very neat in design and are intended for quick operation. |

||||||||

9. Cartridge fuses with porcelain holders are used throughout, and several of the holders were broken. |

||||||||

10. All 110-volt lamps are of the Edison screw type. |

||||||||

Torpedo Charging and Heating |

||||||||

1. There are two motor generators in the aft compartment with inputs of 110-150 volts at 5 amps. These appear to act as boosters to the 110-volt supply for torpedo charging and this output is + 30/-40/-10 volts. |

||||||||

2. There is a flexible lead, one end of which can be plugged into the charging panel, the other end of the lead plugs into the torpedo. |

||||||||

3. No means have been found of charging the torpedoes in the torpedo tubes and it is thought that they may have to be withdrawn to be charged. |

||||||||

4. The supply to the heating circuit for the torpedoes comes through an automatic switch from the V.P. circuit. A changeover switch makes it possible to take the supply from either V.P. panel. |

||||||||

5. The torpedoes can be heated while in the tubes by means of a flexible cable from the torpedo heating plug. |

||||||||

6. The plug which goes into the torpedo goes through a hole in the forward top end of the torpedo tube and then into the side of the torpedo. This hole in the torpedo tube can be made watertight by means of a screw plug on a rubber seating. |

||||||||

7. There is no interlock arrangement to prevent the torpedoes being fired while the plug is in position. |

||||||||

Cables |

||||||||

1. Flexible cables, steel braided, are used throughout the vessel and are rubber insulated. |

||||||||

| 2. Many small cables are used in parallel for the main supply leads (there is no ring main as in British practice). The higher rating of the smaller cables and their flexibility may be an advantage. | ||||||||

| 3. The cables are bunched at each bulkhead and go through a watertight box (one starboard and one port), these boxes are filled with sealing compound and it would be extremely difficult to replace a cable if it should become faulty. There are as many as forty-eight cables in one bunch. | ||||||||

| Telephones and Telegraphs | ||||||||

| 1. Sound power telephones are fitted throughout the vessel; each instrument has a six-way selector switch, a magneto ringer and bell, all instruments are fitted with rubber mountings. The speech is very clear but not very loud and some difficulty is experienced in hearing in engine room when main engines are running. | ||||||||

| 2. A broadcast system is fitted in the vessel; all instruments are mounted on rubber. | ||||||||

| 3. The following equipment is operated by the 110 volts C.P. supply: | ||||||||

|

||||||||

| 4. There is no low power system in the ship. | ||||||||

9 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

LIST OF MACHINES |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brown Boverie et Cie. Akleingesellschaft, Mannheim. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

11 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 |

||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

Resilient Mountings |

||||||||||||||||||||||||||||||||

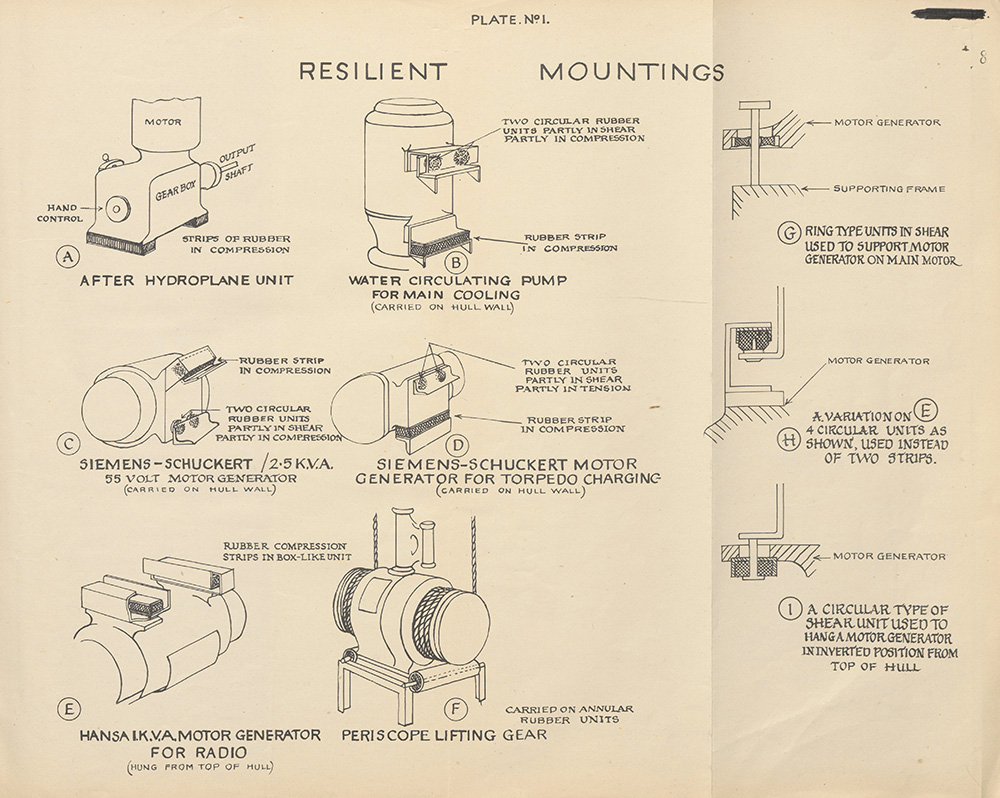

1. It will be observed that almost every auxiliary machine is resiliently mounted. In addition, practically every instrument, indicator, contactor or switch is mounted on small rubber bounded units. The consistency with which this has been carried out whether the apparatus was small or large, is most impressive. As no question of sound insulation can arise in such cases the natural and doubtless correct explanation is that all the resilient mounting of instruments, switch gear and contactors, is to prevent damage by shock. |

||||||||||||||||||||||||||||||||

2. The rubber mounting of auxiliary machinery may be to prevent damage by shock, or alternatively it may be to prevent detection. A further strong possibility is that of preventing local interference with the submarine's own acoustic devices which are extensive. |

||||||||||||||||||||||||||||||||

3. If the reason for providing resilient mounting is to prevent shock damage to machines, then it is difficult to understand why such mountings have been omitted from four machines which are quite as vital to the operation of the ship as many other which have been most carefully insulated from their supports. |

||||||||||||||||||||||||||||||||

4. The reason for omitting to rubber-mount the two h.p. air compressors and the ballast and trimming pumps can, however, be explained without difficulty if the insulation is to prevent noise reaching the water. The h.p. air compressors would only be used on the surface, and alternative methods of trimming by means of compressed air can be used to make operation of the trimming pump unnecessary if quiet conditions are imperative. In addition, the ballast and trimming pumps are auxiliaries which would only be used for short periods, and would not be likely to provide a continuous source of interference with the submarine's own listening devices. |

||||||||||||||||||||||||||||||||

5. It is, therefore, concluded that the primary reasons for sound insulating the auxiliary machinery are to prevent detection and also to prevent interference with acoustic reception, while the resilient mounting of instruments, etc., is to prevent shock damage. |

||||||||||||||||||||||||||||||||

6. A detailed inspection of the methods adopted in providing rubber insulation for auxiliary machinery indicates that a great deal of ingenuity has been used. The three important and outstanding differences between the methods employed when compared with British methods are as follows: |

||||||||||||||||||||||||||||||||

(i) The natural frequency of the machines on their mountings is comparatively high, but very soft rubber is used with a very light loading. |

||||||||||||||||||||||||||||||||

(ii) No attempt is made to provide sound insulation in pipe systems, or in any other mechanical control connection which effectively short circuit the rubber insulation. |

||||||||||||||||||||||||||||||||

(iii) Machines are in no case mounted directly on to the tank tops on large deck surfaces, but are usually carried directly on the hull frames or on light angle frames between deck and hull. |

||||||||||||||||||||||||||||||||

7. With regard to (i), the insulation of very low frequencies under this method may be expected to be less effective, but for the higher frequencies results may well be improved, and the light loading makes compete reliance on rubber to metal bending more satisfactory. |

||||||||||||||||||||||||||||||||

8. Insulation of pressure pipes and mechanical control systems (ii) may possibly have been found to make insufficient difference to warrant the additional complications. |

||||||||||||||||||||||||||||||||

9. The methods of mounting machines vary considerably and the illustrations in Fig. 1 attached shows a selection of those employed. In addition to the machines shown in Fig 1, similar methods are used for other machines as follows: |

||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

13 |

||

10. While the motor generators shown above were, in general, mounted in a similar manner to that shown in Fig. E, and hung from the top of the hull, in some cases the simple compression rubber strips were replaced by smaller circular compression units, and in one case by a type shown at Fig. H. |

||

11. The 6 K.V.A. Hansa motor generator was hung on four circular shear units as shown at Fig. I. |

||

12. The mounting of the periscope lifting gear is rather novel (Fig. F), but it is not known if the rubber extends completely through the tubes shown, or is only a ring of rubber inserted in each end. |

||

GERMAN SUBMARINE CELLS - TYPE 33 MAL. 800W |

||

Examination of Cells |

||

One of the five cells from the main battery of "Graph" was dismantled for examination. The main dimensions of the cell are given in Table 1, together with those of representative British types. |

||

2. The cells are somewhat larger than the standard British cells and somewhat smaller than the large cells used in "Thames" class submarines. The outstanding feature in the design is that a large number of thin plates is used. The negative plates are 3 mm. (3.7 mm. pasted) and the positive plates are 3.5 mm. (4 mm. pasted) thick compared with 5 mm. and 6 mm. respectively for the plates of a "Tudor" cell and 4.75 mm. and 6.4 mm. respectively for the plates of a "D.P." cell. |

||

3. A multiple type of separator, 2.3 mm. thick overall, is used consisting of a corrugated perforated ebonite sheet next to the positive and a plain wooden separator 0.6 mm. thick next to the negative. |

||

Capacity Tests |

||

4. Four of the cells were given a refreshing charge at a low rate and were then subjected to charge and discharge tests in order to determine their capacity at different discharge rates. The cells, during these tests, were immersed in a water bath maintained at 80° F., (the temperature laid down in the Admiralty Specification for Submarine Main Batteries). |

||

5. During the capacity tests, the cells were charged in accordance with the instructions contained in the General Instructions Booklet of Akkumulatoren Fabrik A.G.; that is, the cells were charged at 1650A until the potential difference per cell reached 2.40 volts, the charging rate was then reduced gradually to maintain the voltage constant at this figure until the current fell to 415A at which rate the charge was continued until the cell voltage and the electrolyte density remained constant for one hour. |

||

6. Tests were made with discharge currents corresponding to the nominal 8-hour, 5-hour and 1-1/2 hour rates as given in the General Instructions Booklet and these tests were later repeated in random order. |

||

7. After a full charge, the cells were kept on open-circuit for seven days with the temperature of the bath raised to 100° F., and the capacity at the 8-hour rate was then measured at a temperature of 80° F. The potential of the negative plate as given by a cadmium electrode was 0.34 volt as compared with 0.32 volt at the end of a normal discharge showing that the loss on open circuit (amounting to about 3.5 per cent.) was mainly due to the negative plate. |

||

8. The voltages, given in the General Instruction Booklet for these cells, at which the discharge is to be considered complete, differ from those customarily used for British submarine cells. At both the 8-hour and 5-hour rates, the German end voltage is higher than the British and at the 1-1/2-hour rate it is lower. The discharges were therefore taken to the lower end voltage and the capacity computed to both end voltages. |

||

9. The results obtained in these tests are summarised in Table 2. |

||

| 10. The range of acid densities corrected to 60° F. during discharge at the various rates is given in Table 3 with similar data for a representative British cell. | ||

| 11. The temperature rises of the German cells during discharge and without special ventilation were not excessive being approximately 6° F., 12° F., and 32° F. at the 8-hour, 5-hour and 1-1/2-hour rates, respectively. | ||

| Evolution of Gas | ||

| 12. Whilst the cells were standing on open circuit for seven days at a temperature of 100 F., the rate of evolution of gas was measured daily on two cells. The other two cells could not be made gas-tight. The maximum and minimum gassing rates were 2450 ml/hr. and 220 ml/hr. with an overall mean value of 2200 ml/hr. Typical figures for British cells, when new are given in Table 1; these will be approximately doubled after a year in service. | ||

| Remarks on Results | ||

| 13. The capacities of the German cells at the various discharge rates taken to the end voltages given in the General Instructions Booklet are in close agreement with their nominal capacities. The four cells are uniform in performance and different discharges at the same rate are in satisfactory agreement. | ||

| 14. In comparison with British cells, the German cells have a greater output/weight ratio at all rates of discharge as is shown in Table 4, in which the capacities have been computed to the end voltages laid down in the Admiralty Specification. | ||

14 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

15. The utilisation of the acid and of the active material is better than in British cells; the coefficient of use of the electrolyte is estimated at 71 per cent. for the German cell as compared with 64 percent. for standard British cells of D.P. and Tudor make and the coefficient of use of the positive active material is estimated at 35 per cent. for the German cell and 24 per cent. for a cell of D.P. make. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16. This high performance has probably been obtained at the cost of durability. The large number of thin plates and thin separators which are used give a lower current density, freer diffusion of electrolyte and reduced acid resistance. The fragility of the thin positive plates under anodic corrosion and the lack of support for the paste, will, however, tend towards a shorter life, which it is estimated will not exceed 2 to 2-1/2 years of normal service. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

17. The rate of evolution of gas is very high, about three or four times that of standard British cells after a year's service. Apparently the German makers have made no attempt to deal with this problem. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Summary and Conclusions |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18. Four cells from the main battery of "Graph" were tested at 80° F. and their output measured at their nominal 8-hour, 5-hour and 1-1/2-hour rates. The rate of evolution of gas and the loss of charge while standing on open circuit for seven days were measured. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

19. Comparison has been made with standard plate cells of British manufacture. The German cells have a capacity/weight ratio which is about 45 per cent. higher than that of the British cells, but it is estimated that the life of the cells is only 2 to 2-1/2 years. The rate of evolution of gas is many times greater then of British cells. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Note. The German cells are now (November, 1942) 2-1/2 years old and are still giving good service, but it is estimated that their life will not exceed 3 to 3-1/2 years. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TABLE 1 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Construction of German and British Submarine Cells |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

* Will be approximately doubled after one year's service |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TABLE 2 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Capacities of German Submarine Cells |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

15 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TABLE 3 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Range of Densities of German and British Submarine Cells on Discharge |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(corrected to 60° F.) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TABLE 4 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Comparison of German Submarine Cells and Standard British Flat-Plate Cells |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

*Capacities taken to "British" end voltage. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ship's and Battery Ventilation |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1. The ship's and battery ventilation have one common exhaust trunk running fore and aft throughout the ship. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2. Each cell has its own natural supply from the battery compartment and a 1in. rubber exhaust pipe leading to an ebonite extractor pipe passing through the row of cells. These extractor pipes join inside the compartment and are led away into a suction pipe through the battery compartment crown to the main exhaust trunk. The trunk is exhausted overboard through two hull valves. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3. The ship's and battery ventilation are joined, and a number of methods of ventilating are possible through a cross-over system allowing for either or both fans to be used. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4. The blank end of each extractor pipe over the battery cells has a U tube connection. These U tubes, or manometers, are brought up above the flat, and their indication of the amount of suction in the extractor pipes is the only means of checking that the ventilation is adequate. A reading of 16 mms. of vacuum is equivalent to 100 litres of air per minute passing through each cell. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5. The system is designed for normal discharge overboard, but the discharge overboard is only about 10 ft. above the water line so that outboard ventilation at sea is impossible. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 |

||||||||||||||||||||

CHAPTER III |

||||||||||||||||||||

TORPEDO ARMAMENT AND EQUIPMENT |

||||||||||||||||||||

Armament |

||||||||||||||||||||

Tubes |

||||||||||||||||||||

1. Four bow and one stern internal tubes are mounted, the former being at the fore end of the forward torpedo room and crew space, and the latter at the after end of the motor room. |

||||||||||||||||||||

Torpedoes |

||||||||||||||||||||

2. The probable war torpedo armament is |

||||||||||||||||||||

|

||||||||||||||||||||

3. Torpedoes carried can be either G.7A or G.7E, except in the case of torpedoes stowed in containers, where it is likely that the former will be carried in preference to the latter for maintenance reasons. |

||||||||||||||||||||

Mines |

||||||||||||||||||||

4. Each torpedo storage, except the containers, could accommodate mines, giving a possible total mine stowage of 24 T.M.A. or 36 T.M.B. or T.M.C. |

||||||||||||||||||||

Description of Tubes. (See Torpedo Bewaffnung der U-Boote, Typ VIIB, VIIC und VIID. (ab "U.69") Vorläufige Zeichnungen.) |

||||||||||||||||||||

General Construction |

||||||||||||||||||||

5. The tubes, which are of the close fit type, are made in three sections bolted together, and are supported by feet at the rear end, by the curved pressure bulkhead in the centre, and by a bulkhead at the outboard end. |

||||||||||||||||||||

6. At bow tubes, the central gangway allows access to external adjustment fitting and to one of the two cap operating positions. |

||||||||||||||||||||

7. At these tubes there is no outboard gangway, and all operational gear, except that mentioned above, is at the rear of the tubes. |

||||||||||||||||||||

8. At the stern tubes, the arrangements are similar, a restricted gangway being provided on one side of the tube only. |

||||||||||||||||||||

| 9. The tubes are recessed to take a top lug and the two guides of the discharge piston, the recesses for the latter ending about 3 ft. short of the outboard end of the tube. | ||||||||||||||||||||

| 10. A series of webs is fitted to the outboard end of the tubes abreast the end of the discharge piston guide recesses, and it is presumed that these webs are intended to absorb the shock of arresting this piston. | ||||||||||||||||||||

| Tube Fittings | ||||||||||||||||||||

| Rear Doors, Caps and Shutters | ||||||||||||||||||||

| 11. Rear doors, caps and bow shutters are generally similar to British design. | ||||||||||||||||||||

| 12. The stern cap opens upward, and carries a fixed shutter which conforms to the hull shape when the cap is closed. | ||||||||||||||||||||

| 13. All caps are worked by hand, two operating handles being provided for each bow cap - one in rear of the tube and one in the midship gangway. | ||||||||||||||||||||

| 14. Flooding and Draining. Normal arrangements are fitted for blowing up and draining down between tubes and torpedo tanks (W.R.T. tanks). | ||||||||||||||||||||

| 15. No T.O.T. or A.I.V. tanks are fitted. | ||||||||||||||||||||

| External Adjustment Fittings | ||||||||||||||||||||

| 16. The following external adjustment gears are provided: | ||||||||||||||||||||

| Gyro angling in 1° steps. | ||||||||||||||||||||

| Speed - High, medium and low. | ||||||||||||||||||||

| Depth - 0-12 metres in 0.5 m. steps. | ||||||||||||||||||||

| 17. The gyro angling gear can be set by hand either at the gear box in rear of the tubes, or at angling gear on each tube, or by electric power from the director angle calculator. | ||||||||||||||||||||

| 18. The gyro angling gear is normally engaged by hand after loading, and remains locked in this position until automatically removed by the operation of the firing lever. | ||||||||||||||||||||

17 |

||

Access Fittings |

||

19. An access pocket is provided for battery heating of G.7E torpedoes. |

||

Top Stops and Trippers |

||

20. The torpedo top stop and tripper are in the same casting, the former being lifted and the latter being swung to the rear, thus throwing the air lever back, by the movement of the firing shaft. |

||

21. The mine top stop takes against the top lug of the foremost mine, and must be raised by a hand lever and operating shaft before either mine or torpedo firing gear can be worked. |

||

22. Before loading the tube with mines, the torpedo stop and tripper are raised and swung aft respectively by a lever on the stop and tripper box, and the mine stop is lowered. |

||

Safety Arrangements. (Vide Interlocks) |

||

23. Every possible combination of events which might cause an accident has been guarded against by interlocks and other safety devices. |

||

24. This policy has necessitated the provision of a special interlocking shaft which acts as an intermediary between the various operations to prevent them being carried out in incorrect sequence. |

||

Discharge Control Gear |

||

Torpedo Discharge |

||

25. Submerged discharge is effected by admitting air behind a close fit piston in rear of the torpedo. |

||

26. For A.W. fire, air is admitted in front of the piston by means of a change-over cock, which, when put to A.W. fire, locks the piston to the tube. |

||

27. The piston is fitted with a central shaft, which carries a spring loaded plunger whose front face bears against the tail of the torpedo. |

||

28. The after face of the plunger bears against an adjusting screw passing through the centre of the rear door, and this screw is set up after loading, as necessary, to keep the torpedo against the torpedo top stop. |

||

29. The discharge control gear at each tube consists of |

||

(a) L.P. firing reservoir (73/4 cu. ft. capacity, maximum pressure of 425 lbs. per. sq. in.) |

||

(b) Small firing valve. |

||

(c) Large firing valve (no dashpot). |

||

| (d) Impulse cut-off valve. | ||

| (e) W.N.R.V. with change-over cock (submerged or A.W. discharge). | ||

| (f) Impulse release valve. | ||

| 30. The cycle of operations for submerged discharge is generally similar to that of British L.P. firing gear up to the point of cut-off and the opening of the impulse release valve. | ||

| 31. Thereafter, the exhausting of the air behind the piston and the water pressure in front of it combine to return the piston to the rear of the tube. | ||

| 32. The impulse release valve will remain open until the firing gear is recocked and the firing reservoir charged to a pressure in excess of cut-off pressure. | ||

| 33. When discharging from the surface, the impulse release valve is blanked by the piston, and does not operate. | ||

| 34. The discharge control gear does not provide compensation for change of trim after firing. | ||

| 35. Impulse pressures of approximately 155 and 240 lbs. per sq. in. are used for submerged and A.W. torpedo discharges respectively. | ||

| Mine Discharge | ||

| 36. The 2 T.M.A. or 3 T.M.B. or T.M.C. mines carried in the tube are held in position by a mine top stop against the top lug of the outboard mine and by the central shaft of the piston bearing against the after end of the inboard mine. | ||

| 37. Mines are normally fired singly, air being admitted behind each mine in succession from outboard through connections on the side of the tube. | ||

| 38. Air for this purpose is supplied from the H.P. air line, and passes through a mine firing valve and a selector valve, air leads from the latter going to each of the four connections on the tube for either 2 T.M.A. or 3 T.M.B. or T.M.C. mines. | ||

| 39. Once the outboard mine has been fired, the remaining mines are no longer held rigidly in the tube, and all mines in the tube must presumably therefore be fired in succession at short intervals. | ||

40. All mines in the tube could, if necessary, be fired simultaneously by the torpedo discharge gear. |

||

| 41. When discharging mines by the normal method, there appears to be no means of gauging the impulse required, and it is presumed that pressure is applied until the mine is heard to leave the tube. | ||

| (C50426) | ||

18 |

||

Torpedo Firing Gear |

||

42. The firing gear consists of a spring-loaded firing rod, which is cocked by the interlocking shaft when closing the cap, or by an hand lever, and is held in the cocked position by a trigger sear. |

||

43. The trigger sear can be slipped, either by an electro magnet energised from the firing position through the automatic firing gear, or by a hand firing-rod at the tube. |

||

44. A safety bolt with "ready" and "safe" positions is provided to hold the firing rod in the cocked position until shortly before firing. |

||

45. On firing, the firing rod disengages the gyro angling gear, lifts the top stop, works the tripper, and pushes the small firing valve off its seat. |

||

46. The automatic gear consists of a form of timing switch, which on being set in operation by the firing switch, energises in succession the firing circuits of each tube to be fired. |

||

47. The selection of firing position to be used and of the tubes to be fired is set on selector switches in the control room. |

||

48. When firing a bow salvo the tubes are fired in the order I, III, II, IV, and the time for the whole salvo, when using automatic firing gear, is 8 seconds. |

||

49. When firing locally, a firing interval of 2-1/2 seconds is used. |

||

Note. A recent order from Vice-Admiral U-Boats, which was found on board, stated that the firing interval was not to be less than 8 seconds owing to the danger of collision. This adjustment to the firing interval timing switch had not been made. |

||

Handling Arrangements |

||

Torpedoes |

||

Embarkation |

||

50. Inboard Stowages. No derricks are fitted, and torpedoes have to be lifted onboard by external means. |

||

51. Embarking trays, which are common to both forward and after embarking positions, are fitted in sections in a straight run between the deck and a position just inside the torpedo hatch. |

||

52. The torpedo is eased down the trays by a two-legged sling shackled to a wire pendant, the legs of the sling being attached to the torpedo by lugs engaging in recesses in either side of the afterbody. |

||

53. At the end of the trays, the torpedo is taken over by the loading beam, which is tilted parallel to the trays by the two purchases on which it is carried, the torpedo being secured to a trolley on the beam by a lifting band. |

||

54. The torpedo is then eased down the beam until the tail is clear of the hatch, the inboard section of the tray is unshipped, and the beam and torpedo leveled by the purchases. |

||

55. The purchases are then traversed over the required stowage on transverse rails, and the loading beam and torpedo lowered into position. |

||

56. Torpedoes stowed on chocks or loading beams in the forward torpedo room must be embarked with heads unshipped. |

||

57. Container Stowages. Containers, which are before and abaft the forward and after torpedo hatches respectively, can be tilted on trunnions at their "head" end, thus allowing the end door to be removed and the torpedo to be entered and launched in. |

||

58. When embarking from containers, the torpedoes are hauled back on trays over the torpedo hatch, and on to the top embarking tray which can be tilted up to the required angle. |

||

| 59. The intermediate trays are then removed, the top embarking tray tilted down, and the torpedo embarked in the normal manner. | ||

| Loading | ||

| 60. Torpedoes are picked up by the loading beam and traversed to the loading position, where the beam is secured by special stays. | ||

| 61. The torpedo is then run into the tube on the trolley, and launched home by tackle and tail eye bar. | ||

| Mines | ||

| 62. Handling of mines is carried out on similar lines to handling of torpedoes - the loading beams being fitted with trolley locking pin holes to provide for the various types of mines and the positions they have to occupy during the different phases of embarkation, stowage and loading. | ||

| Maintenance Arrangements | ||

| Tubes | ||

| 63. Lubricating points for all fittings outside the pressure hull are connected by pipe lines to lubricating caps in a box under a deck plate in the casing. | ||

| 64. Internal greasing points are fitted with red caps, and are clearly visible | ||

| 65. After firing, the piston and inside of tubes are liberally greased. | ||

19 |

||

Torpedoes |

||

66. Normal air charging arrangements are provided. |

||

67. A small low pressure test set is provided, and this set, which consists of a reducer and the necessary pressure gauges, is fed from the H.P. air service. |

||

68. The battery charging for G.7E torpedoes is done by a special generator through a charging switch and flexible charging lead. |

||

69. When charging, a ventilating door is fitted to the torpedo in place of one of the access doors, and a catalyser is used to deal with the hydrogen given off. |

||

70. Battery heating for G.7E torpedoes is done by a special circuit through a timing switch, which is connected by flexible lead to the heating connection on the torpedo through the access pocket in the tube. |

||

Torpedo Control |

||

71. Torpedo fire is controlled from the conning tower or from the bridge; electric firing pistols are fitted in both these positions. |

||

72. There are three sighting positions - the two periscopes and the night director fitted on the bridge. Each of these is fitted with an electrical relative bearing transmitter. The position in use is connected to a receiver in the calculating instrument by a selector switch on the control panel. |

||

73. The night sight consists of a pair of very good pressure-tight binoculars on a revolving mounting. It is a line of sight transmitter only and has no means of calculating the director angle other than the calculating instrument. Torpedo control by night is the same as by day. |

||

The Calculating Instrument |

||

74. The calculating instrument is in the conning tower close to the attack periscope. It is considerably more elaborate than the British Submarine Torpedo Director and has a large number of dials but it does not give a clear picture of the relative position of own and enemy ships as does the British instrument. |

||

75. The calculator performs the following functions: |

||

A. Calculation of Director Angle |

||

Settings |

||

(i) Torpedo speed. Three positions 44, 40 or 30 knots set by hand. |

||

(ii) Enemy speed. 0 to 40 knots set by hand. |

||

(iii) Inclination. Set by hand in the first instance and then corrected automatically for change of bearing. This gear must be switched off when resetting inclination by hand. |

||

76. The resultant director angle is shown on a dial on the face of the instrument. |

||

| B. Calculation of Gyro Angle | ||

| 77. The instrument generates the gyro angle from the formula G.A. = Line of sight (relative bearing) + Director angle + Convergence. | ||

| Settings | ||

| (i) Line of sight. Received electrically from the sight in use. A hand follow-up applies it to the instrument. When the sight is not being kept continually trained on target a switch is made which burns a blue lamp in the calculator to indicate "Do not follow." | ||

| (ii) Bow or stern tubes. Set by hand switch on the instrument and ensures gyro angle and convergence are applied in the right direction. | ||

| (iii) Range. Set by hand. | ||

| (iv) Rate of swing. Set by hand (degrees/second). The purpose of this setting is to apply a correction to the gyro to allow for swing when firing a salvo with the submarine under helm. | ||

| Note. There is no indication that hydrophones or other detecting devices are used to give a "line of sight" for firing blind. | ||

| 78. The gyro angle generated is shown on the face of the instrument and is transmitted to the receivers at the bow or stern tubes through a selector switch on the control panel. | ||

| C. Calculation of Spread Angle | ||

| 79. Settings | ||

| (i) Range. As above. | ||

| (ii) Inclination. As above. | ||

| (iii) Length of target. Set by hand. | ||

| 80. The total angle of spread is shown on a dial on the face of the instrument and is transmitter to the receiver at the bow tubes. | ||

| (C50426) C2 | ||

20 |

||||||||||||||||||||||||||

The Control Panel |

||||||||||||||||||||||||||

81. The control panel is in the control room, it forms a junction box for the torpedo control circuits and carried the following selector switches: |

||||||||||||||||||||||||||

(i) Line of sight. Two periscopes or night sight. |

||||||||||||||||||||||||||

(ii) Gyro angle. Bow or stern tubes. |

||||||||||||||||||||||||||

(iii) Firing circuit I. Each tube separately or "salvoes." |

||||||||||||||||||||||||||

(iv) Firing circuit II. Various combinations of 2-, 3-, and 4-tube salvoes. |

||||||||||||||||||||||||||

Gyro and Spread Angle Receivers |

||||||||||||||||||||||||||

82. The gyro and spread angle receivers at the bow tubes are mounted in a gear box with hand or automatic follow-up gear. Following the pointer in the gyro angle receiver operated a mechanical drive to the external angling gear on each tube. Any angle between 0° and 90° R. or L. can be set in 1° steps. |

||||||||||||||||||||||||||

83. The spread angle receiver is fitted with a selector switch which can be set for three different "spread methods." Following the spread angle pointer applies a correction to the mean gyro angle transmitted to each tube. |

||||||||||||||||||||||||||

84. The gyro angle receiver at the stern tube is fitted with a hand-operated follow-up, which works a mechanical drive to the external angling gear on the tube. |

||||||||||||||||||||||||||

Firing Methods |

||||||||||||||||||||||||||

85. Three methods of firing are used. Salvoes, multiple shots and single shots. |

||||||||||||||||||||||||||

86. In salvo firing No. 1 selector switch is set to "salvoes" No. 2 to the particular combination of tubes to be fired. On pressing the firing pistol the first torpedo is fired and an automatic timing relay is energised which fires the remainder in succession with the minimum firing interval. This interval is stated to be 3 seconds, but it is known that later instructions have been issued that the firing interval is to be not less than 8 seconds. |

||||||||||||||||||||||||||

87. In "multiple" shot firing torpedoes are fired singly on the same course at 8 seconds interval. The first shot is aimed ahead of the centre of the target a distance equal to two times enemy speed, in metres. |

||||||||||||||||||||||||||

88. In single shot firing each torpedo is aimed and fired separately. |

||||||||||||||||||||||||||

Communications |

||||||||||||||||||||||||||

89. Communication between the control positions and the tubes is by loud speaker telephone and voicepipe. Tube ready lamps boxes are fitted in the control room and at the tubes. |

||||||||||||||||||||||||||

Interlocks |

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

21 |

|||||||||||

|

|||||||||||

*This arrangement is shown on the drawings, but is not actually fitted in "Graph." |

|||||||||||

NOTES A-D |

|||||||||||

NOTE A |

|||||||||||

"GRAPH" |

|||||||||||

Mine Discharge |

|||||||||||

Three mines can be loaded into and fired from each torpedo tube, discharge air, direct from the H.P. air line being admitted through a selector cock to the rear of each by a stop. Once minelaying commences; all mines in the tube must be fired in succession at short intervals. |

|||||||||||

British Practice |

|||||||||||

Only one mine can be loaded into and fired, by the normal torpedo discharge fitting, from each tube. |

|||||||||||

NOTE B |

|||||||||||

Splashless Torpedo Discharge |

|||||||||||

"GRAPH" |

|||||||||||

| A steel disc is loaded into the close fit torpedo tubes in rear of the torpedo. Discharge air, admitted behind the disc, drives it and the torpedo forward till checked by a buffer arrangement. The automatic opening of a vent cock releases this air inboard, the disc being returned to the rear of the tube by sea pressure. The admission of water to compensate for torpedo firing is carried out by hand through an accurate flow-meter. | |||||||||||

| British Practice | |||||||||||

| Inboard venting of discharge air and admission of the correct weight of compensating water is carried out automatically. | |||||||||||

| Advantages of German Practice | |||||||||||

| (a) The torpedo firing gear is simpler. | |||||||||||

| Advantages of British Practice | |||||||||||

| (a) The venting of the tube and compensation are fully automatic. | |||||||||||

NOTE C |

|||||||||||

Gyro Angling |

|||||||||||

"GRAPH" |

|||||||||||

| Any gyro angle between 0° and 90° R or L can be set automatically. | |||||||||||

| British Practice | |||||||||||

| Straight running or 90° angles only are used. The external angling gear on each tube must be set separately by hand. | |||||||||||

| Advantages of German Practice | |||||||||||

| (a) Greater freedom of manoeuvre. | |||||||||||

| (b) Snap shots can be fired without having to alter course. | |||||||||||

| Advantages of British Practice | |||||||||||

| (a) Simplicity of control procedure and equipment. | |||||||||||

| (b) Saving in weight and maintenance. | |||||||||||

| (C50426) C3 | |||||||||||

22 |

||

NOTE D |

||

"GRAPH" |

||

Salvoes are spread by applying a correction to the mean gyro angle and firing with the minimum firing interval. |

||

British Practice |

||

Salvoes are spread by varying the firing interval. |

||

Advantages of German Practice |

||

(a) The salvo is fired in minimum time. |

||

(b) Torpedoes reach the target at the same time and are more difficult to avoid. |

||

Advantages of British Practice |

||

(a) Simplicity of control procedure and equipment. |

||

(b) Saving in weight and maintenance. |

||

Disadvantages of British Practice |

||

(a) Against a slow target the firing intervals are large and the firing of a complete salvo takes a long time during which the submarine is exposed to counter attack. |

||

(b) Torpedoes are easier to avoid. |

||

23 |

||||||||||

CHAPTER IV |

||||||||||

GUNNERY |

||||||||||

Section I. Guns and Mountings |

||||||||||

Details of the 8.8 cm. Gun and Mounting |

||||||||||

1. Inscription (vide para. 23): |

||||||||||

On gun. 8.8 cm. SKC/35. Nr. 169. |

||||||||||

On cradle. Gerwucht der Wiege einsche Visler 459 kg. |

||||||||||

On mounting. 8.8.cm. SKC/35 |

||||||||||

8.8 Ubt LC/35. |

||||||||||

Training and Elevating System |

||||||||||

2. The gun can be trained and elevated from both sides. The training base itself is watertight. The lubrication arrangements are very elaborate and good. |

||||||||||

3. Rendering devices, similar to British practice, are fitted in both elevating and training worm-wheels |

||||||||||

4. A simple form of positive depression control gear is fitted which is operated by a roller on a cam rail. The shaft to which the roller is attached leads through the centre of the vertical training shaft and prevents the gun from being depressed on to dangerous bearings by coming up against the bottom of the recoil and run out cylinders. A hinged portion of the depression cam allows the gun to house at horizontal and on fore and aft line. |

||||||||||

5. The elevating gear is simple and works smoothly. Adjustment for backlash has to be made by introducing shims as necessary. There was no "jar" in the elevating handwheel when the gun was fired. |

||||||||||

6. The free flooding holes in the mounting are fitted with weed trap gratings which might tend to freeze over in very cold weather, but the casings are so well drained that it is not likely that the gear itself would be frozen up. |

||||||||||

7. The efforts are good and are as follows: |

||||||||||

| ||||||||||

8. There was a slight tendency to "jar" when altering the speed of training, but with the fairly high rates of 4° per rev. of handwheel this is to be expected. |

||||||||||

| Lubrication | ||||||||||

| 9. The lubrication system consists of an arrangement of grease gun nipples and pipes leading to all bearings in the elevating and training system. | ||||||||||

| 10. The watertight nipples are collected together in a free-flood compartment in front of the pedestal in which is also contained the clutch mechanism described in paragraph 3. | ||||||||||

| 11. This system is considered to be an advance of any system used in small British mountings where quick and easy maintenance is extremely important. | ||||||||||

| Sighting Arrangements and Telescopes | ||||||||||

| 12. Interesting features are the provision of a temperature corrector and three alternative scales for various M.V.s A free pendulum mounted in a receiver on the trunnion axis gives the effective roll on the bearing on which the gun is trained. It is understood that this is used by the officer of quarters in bad weather conditions to prevent the layer firing when his trunnions are canted and thus to prevent cross-leveling error. | ||||||||||

| 13. The telescopes are pressure- and water-tight with a free flood streamline cover over the object glass. | ||||||||||

| 14. The telescopes are arranged so that the layer and trainer both use the same telescope when working on the same side of the mounting; otherwise the second eyepiece can be used as a verifying sight. | ||||||||||

| 15. The optical properties of these telescopes are not very good on account of the large number of air/glass surfaces. | ||||||||||

| Firing Mechanism | ||||||||||

| 16. The firing mechanism was cross connected and consisted of a palm firing lever fitted at both sides of the mounting and a push rod operating along the cradle at the left side of the gear. A lever for firing by lanyard was fitted. | ||||||||||

| 17. Efforts to fire were as follows: | ||||||||||

|

||||||||||

| (C50426) C4 | ||||||||||

24 |

||

| Breech Mechanism | ||

| 18. The Breech mechanism is of the vertical block type and can only be worked in Q.F. | ||

| 19. The general operation of this breech is not liked and is inferior to the 4-in., Mark XII, mechanism. | ||

| 20. The B.M. lever is awkward to operate and ejection is not up to the standard of the British 4 in. gun. | ||

| 21. A small point to the advantage of the German breech is that the striker bar shaft projects to the rear and it is easy to see if the striker has gone forward. | ||

| Diving | ||

| 22. The gun is fitted with a watertight tampion and breech plug when diving. | ||

| 20 mm. Gun Details of the Gun and Mounting | ||

23. Inscription. 2 cm. Flak. Waffe Nr. 4018-1941. |

||

24. The gun is substantially the same as that seen in H.M.S. "Excellent" but is adapted for fitting in U-Boats and has the following minor differences: |

||