|

|||||

FORMER GERMAN SUBMARINE TYPE IXC |

|||||

TORPEDO HANDLING, LOADING AND STOWAGE |

|||||

SUMMARY |

|||||

| The handling, loading and stowage of torpedoes on the type IXC submarines is different in many respects from American practice. The German used lighter handling and stowage equipment in the forward and after rooms, but on the contrary, used a large number of topside stowage tubes to carry sufficient spare torpedoes. No particular effort was made to provide handling and stowage gear for rapid reload. | |||||

February, 1946 |

|||||

PORTSMOUTH NAVAL SHIPYARD, PORTSMOUTH, N. H. |

|||||

- 1 - |

|||||

9C-S75-3 |

||

| 1. INTRODUCTION | ||

| The Type IX C German submarine retains the same basic below deck handling and stowage arrangements as its predecessors, the Type VII submarines. However, more reserve torpedoes can be handled on this later type mainly because of the additional topside stowage tubes provided. | ||

| 2. GENERAL DESCRIPTION | ||

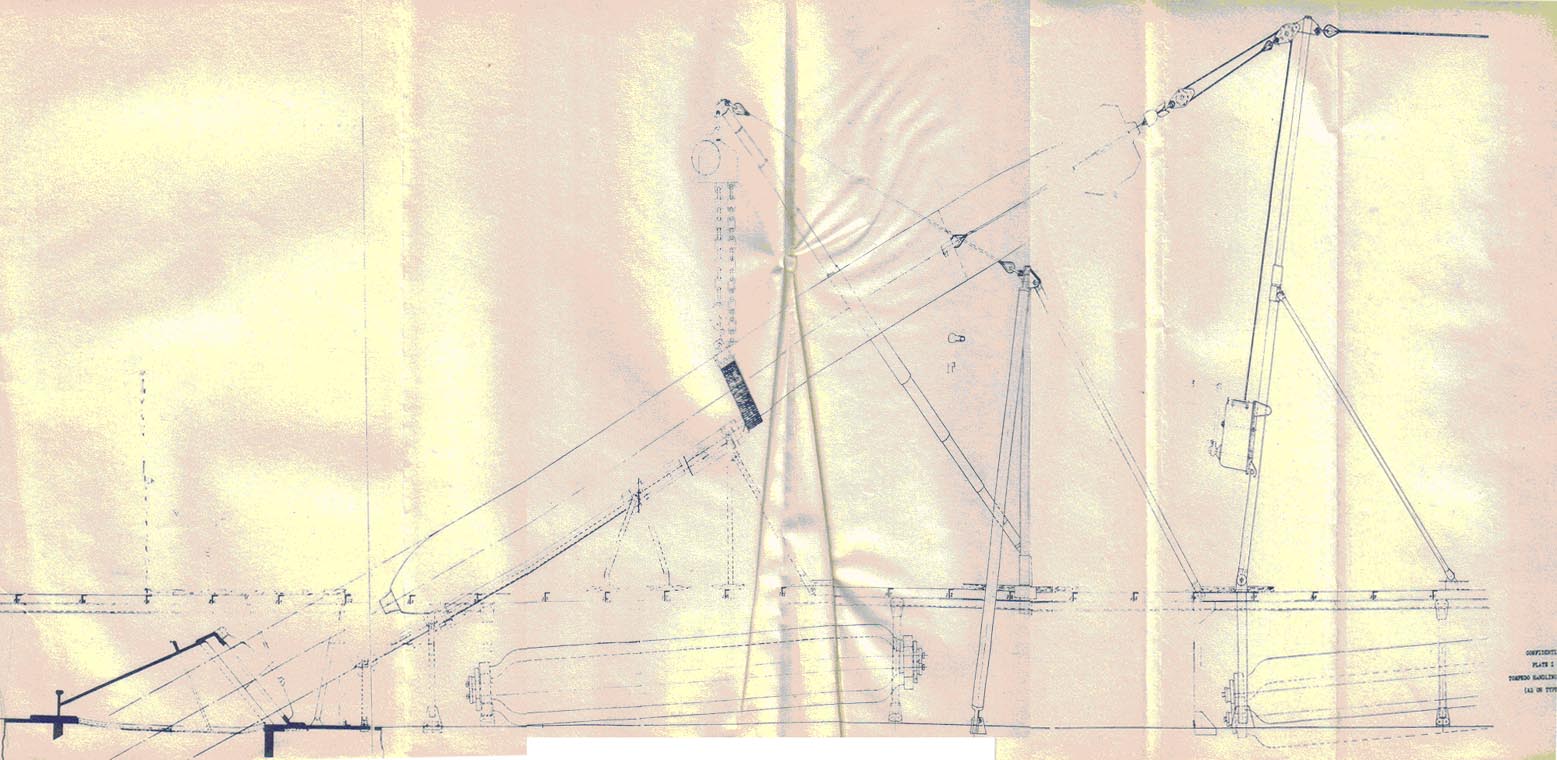

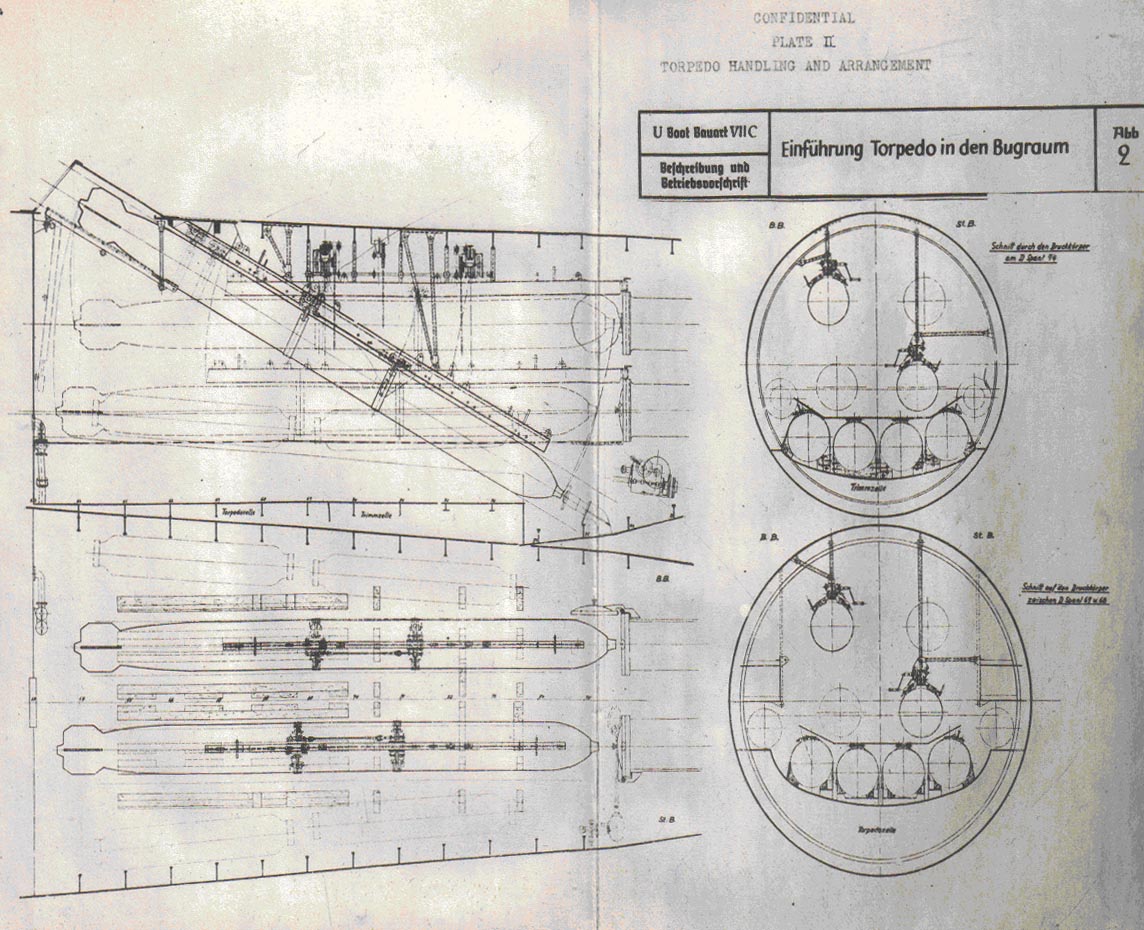

| The principles of the stowage and handling of torpedoes in the torpedo rooms on the IX C are shown on Plates I and II. | ||

| The topside torpedo handling gear varies from U.S. practice in several features. Additional deck arrangements, such as tracks and a dolly, are made necessary by the Germans' extensive use of topside stowage to supplement limited below-decks stowage. The main difference, however, arises from the German practice of lowering the torpedo into the vessel by means of a fitting attached to the after body of the torpedo. The use of this fitting requires an additional high stanchion with its guide wires and fittings clear of the loading hatch. On the IX C a cable arrangement to the deck winch is used for lowering the torpedo into the vessel in lieu of the pulley and crank arrangement shown on plate I. The upper loading cradle is large and presents a stowage problem. U.S. designs utilize the cradle as part of the deck planking. | ||

| Within the vessel no heavy loading cradles are used either for supporting the torpedoes in their stowage or for loading into the vessel. Instead, for stowage, light supporting chocks are used and, for all transport and loading operations, a portable I-beam with its associated rollers and torpedo supporting gear is used (see plate II). | ||

| When lowering the torpedo into the vessel, using the I-beam, an additional short supporting cradle is needed just inside the loading hatch. As the torpedo enters the room, supporting straps from rollers on the I-beam, which has been previously secured in position, are placed around the torpedo. This is am awkward process and adds to the loading time. After the torpedo is lowered against a lower stop, the upper supporting cradle is removed, the I-beam and torpedo are placed in a horizontal position, are moved athwartships by means of two interconnected differential chain hoists and a trolley, and the torpedo is lowered into the chocks. | ||

- 2 - |

||

9C-S75-3 |

||

| The torpedo is then removed from the I-beam and secured in the chocks. This latter process is also time consuming. On U.S. designs the torpedo is already in its stowage cradle and needs but to be rolled athwartships once the cradle is lowered to the horizontal position. | ||

| The utilization of the forward and after torpedo room spaces for combined berthing and stowage facilities seems to favor American designs. The IX C has the trim and WRT tanks within the pressure hull in both the forward and after torpedo rooms. Four reserve torpedoes forward and two aft are stowed over these tanks and below the compartment floor plates. In the forward torpedo room above the floor plates and in an average cross sectional area of approximately 75 sq.ft., ten berths are fitted. In the after torpedo room in an area of approximately 55 sq.ft., 8 berths are fitted. None of this upper space is utilized for carrying reserve torpedoes. On latest U.S. designs, in the forward room above the deck plates in an average sectional area of approximately 125 sq.ft., 8 torpedoes and 17 berths are stowed; and in the after room 14 berths are provided. As all tubes, both forward and aft, are above the floor plates, no reserve torpedoes are on the same level as any of the tubes to be serviced. On the latest American submarines the practice has been to supply two reserve torpedoes for all torpedo tubes at the same level as the tubes, with the exception of the upper tubes aft, in which case only one spare for each tube is provided. | ||

| On the IX C the chain hoist arrangement in each torpedo room for handling torpedoes is built into the ship's structure. Each of the two hoists is arranged on an athwartships trolley. A shaft and gearing mechanism between the trolleys permits simultaneous athwartship movement of the hoists. This built-in arrangement is more convenient than the portable one used on U.S. submarines but does occupy space that can be used for berthing. The arrangement provides positive control of the movement of the torpedo but does limit the speed at which it may be moved athwartships. | ||

| The German technique of loading the torpedoes from the spare stowage has been adapted from that used on earlier types and is a slow cumbersome method. Preliminary arrangements for loading the torpedo into the tube are not completed until the torpedo is raised from its stowage under the deck and lined up with the tube to be serviced, and the I-beam is secured into position by the special securing rods provided. This handling and loading gear is light when compared with heavy cradles and supporting cross beams. However, the sacrifice on reloading times is excessive. The arrangement adopted | ||

- 3 - |

||

9C-S75-3 |

||

| on U.S. submarines requires no excessive amount of handling of the torpedoes prior to reloading. Under most normal circumstances when readying for reload, the cradle (and its torpedo), being on the same level as the tube, need only be rolled athwartships and secured in its loading position by a simple built-in locking device. | ||

| An attempt has been made to reduce noise transmission during handling operations by mounting the chain hoisting gear on rubber. The details of these mountings will be covered under the S40 reports on shock and sound isolation. | ||

| The practice of lowering away the torpedo by attaching to a fitting on the after body has been accepted with much favor by American crews operating the German gear. The main advantage of this over the American method lies in the fact that the lines leading to the deck do not have to pass the maximum diameter of the torpedo. There is no resulting chafing and binding of the cable or rope used, and the diameter of the entrance opening for the loading hatch can be kept at a minimum. Also special torpedo nose fitting for the different types of torpedoes are not required; the cable is attached to the torpedo by means of a light hook that fits into a recess built into the torpedo. When lowering away any large number of torpedoes , the added simplicity of this method becomes more apparent; also the labor required to install the high stanchion involved by this technique becomes minor in nature. | ||

| 3. CONCLUSION | ||

| The total number of reserve torpedoes carried on board the type IX C submarine counting both topside and torpedo room stowage is comparable to total reserve carried on U.S. submarines. However, the inaccessible stowage space allotted these reserve torpedoes and the cumbersome gear required for handling then does not permit rapid reloading of the tubes. It is recommended that no further study be made of the setup as installed on this type. | ||

- 4 - |

||