|

|||||

FORMER GERMAN SUBMARINE TYPE IX-C |

|||||

VENTILATION, AIR PURIFICATION AND OXYGEN RENEWAL |

|||||

SUMMARY |

|||||

| The Type IX-C German submarine is equipped with a flexible ventilating system, and elaborate air purification and oxygen renewal system. Battery ventilation is provided from the ship's ventilation system; however, no air conditioning coils or other cooling means are provided for humidity control. | |||||

| The design of the ventilation system forms an interesting comparison with U.S. Submarine practice. Although the quantity of air renewal and recirculation are approximately equivalent, the compromises in design to arrive at a satisfactory ventilating system are markedly different. Duct velocities are higher in the german design, resulting in smaller duct sizes and higher blower horsepower ratings, and produce optimum operating conditions at less the maximum capacities. | |||||

February, 1946 |

|||||

PORTSMOUTH NAVAL SHIPYARD, PORTSMOUTH, N. H. |

|||||

- 1 - |

|||||

9C-S38 |

||

C O N F I D E N T I A L |

||

VENTILATION, AIR PURIFICATION AND OXYGEN RENEWAL |

||

| 1. INTRODUCTION | ||

| This report will amplify the statements made in the NavTechMisEu report No. 309-45 on the same subject. The operation of the systems under varying surface and submerged conditions has been adequately covered and will not be included. The main discussion will be devoted to the design features of the various systems. | ||

| 2. DESCRIPTION | ||

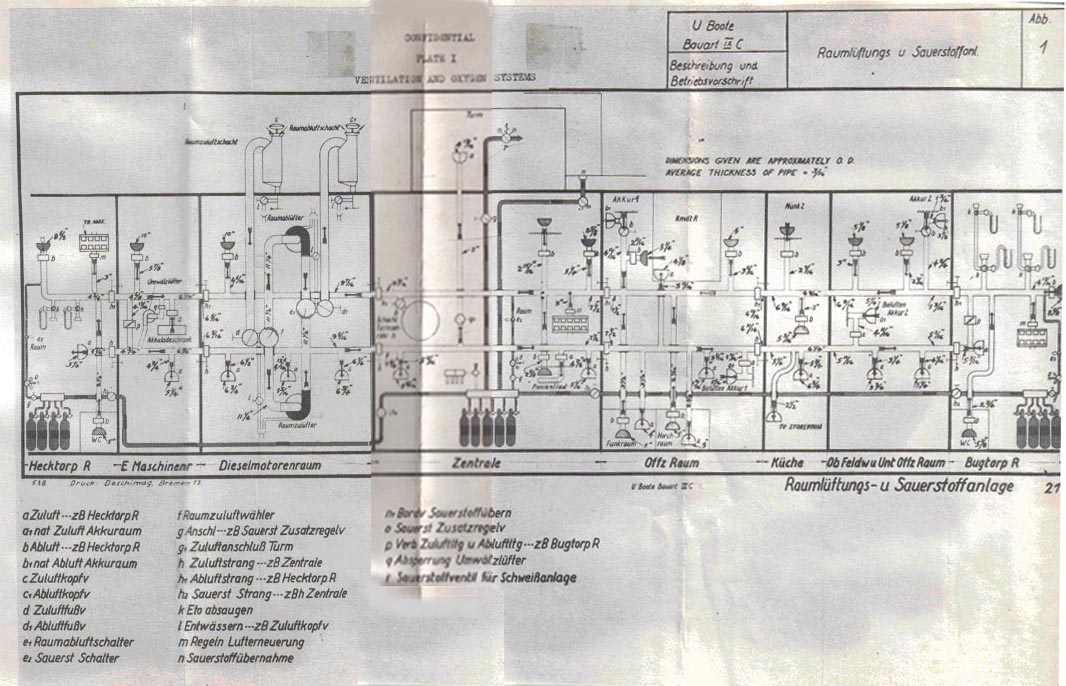

| A schematic arrangement showing the ventilation, air purification and oxygen renewal systems is given on plate I. A study of this plate will show that the general arrangement of each of these systems differs from U.S. practice in numerous respects. | ||

| Of particular interest is the arrangement and functioning of the ventilation system. The American practice has been to omit exhaust piping in the after part of the vessel, thereby reducing the required capacity of the exhaust blower. Instead, exhaust ventilation of the after compartments is provided during surface running from operation of the diesel engines, and during submerged operation by the natural exhaust through bulkhead flappers and doors. The Germans have installed supply and exhaust ducts in all compartments and have arranged the piping and blowers so that either or both blowers can take a suction from the exhaust line and discharge to the supply line. This gives positive supply and exhaust ventilation for all compartments and flexibility in blower use but requires a larger exhaust blower and much additional ventilation piping. No battery blowers are installed but are not necessarily required because of the flexible operation of the ship's ventilation system. Of note is the installation for use during silent running of a quiet, low capacity blower (umwältzlufter). | ||

| More elaborate air purification and oxygen renewal systems have been installed. Removal of CO2 is accomplished by insertion of sodium hydrate cartridges into special manifolds attached to the ventilation exhaust line. Measurement of CO2 concentration is made with use of air sampling tubes, a Drager-measuring apparatus, or an Orsat testing setup. | ||

- 2 - |

||

9C-S38 |

||

| Oxygen renewal is also accomplished through the ship's exhaust system. The oxygen bottles are placed in three banks, each bank with a separate manifold. Lines lead from these manifolds to the ship's exhaust line. It is possible to bleed oxygen directly into the torpedo rooms or control room. | ||

| 3. INDIVIDUAL COMPONENTS | ||

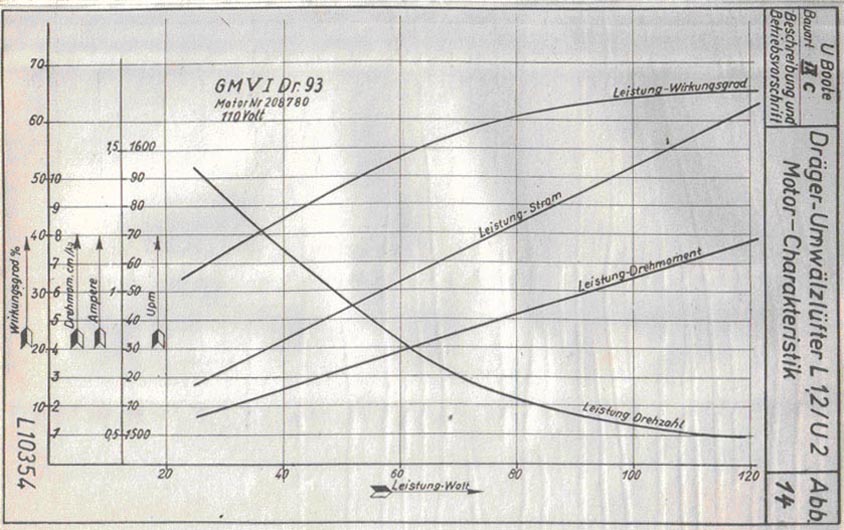

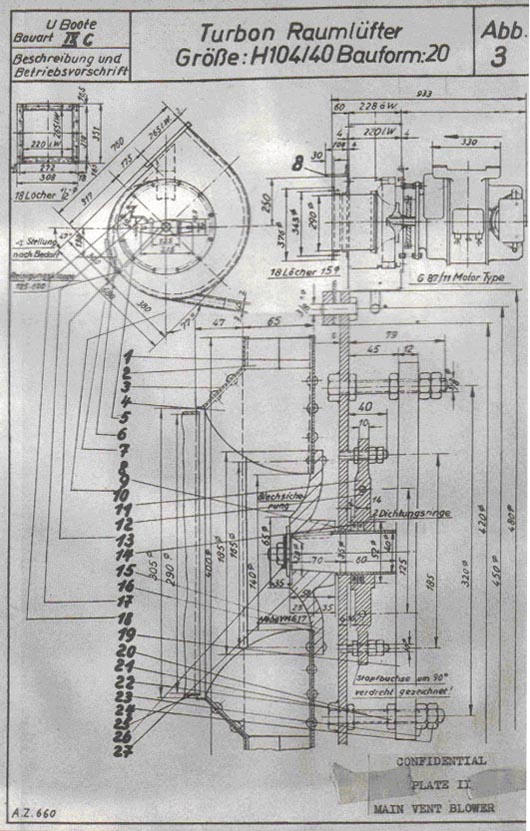

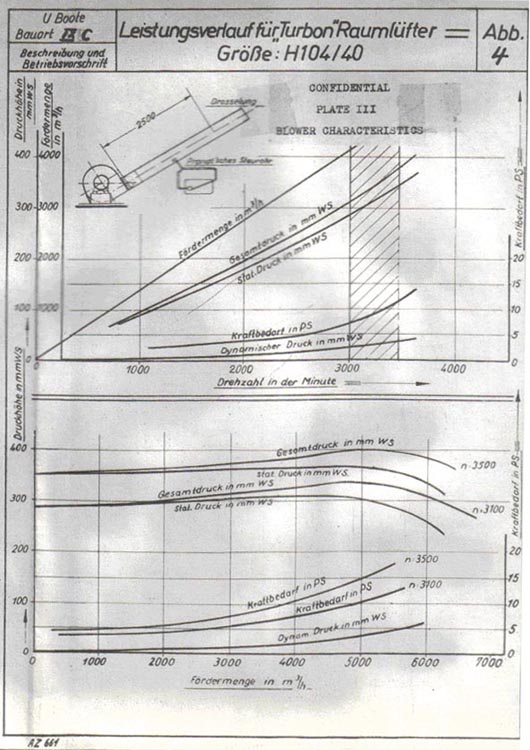

| The details and operating characteristics of the main blowers are shown on plates II and III respectively. Rheostat control of the motor shunt fields and switching arrangements to put the motor armatures in either series of parallel are provided to give a wide range of blower operation. This design is of interest to indicate approximate weights, sizes and horsepower requirements, if resort to a higher speed blower of similar characteristics is contemplated. | ||

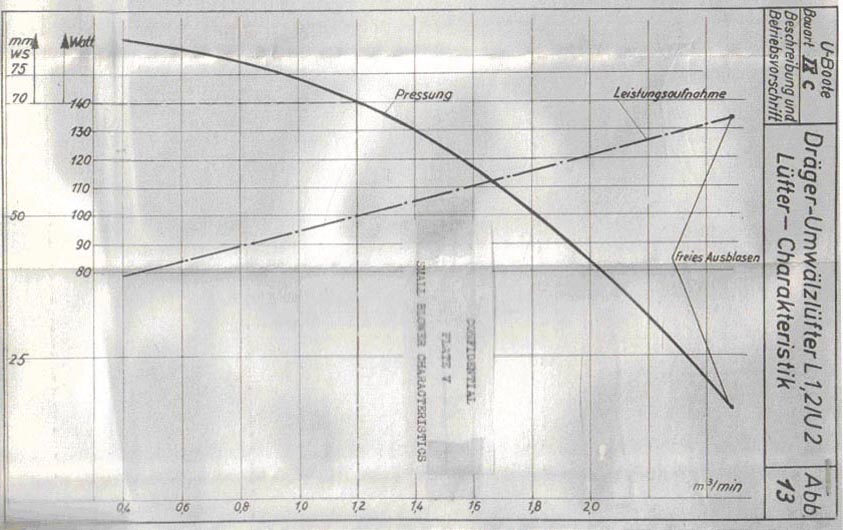

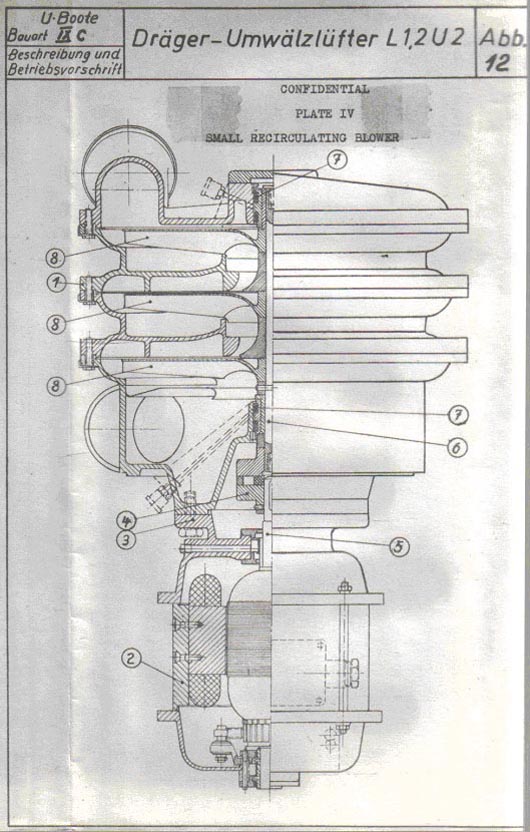

| The details and operating characteristics of the small low capacity blower (umwältzlufter) are given on plates IV and V respectively. This blower has 3 stages in series, producing the required static head at a low delivery rate. In addition to being operated during silent running, the blower was frequently used during normal operations in the interests of fuel economy. It is doubtful that this blower is of adequate capacity to provide sufficient recirculation of air. It seems highly desirable, however, to have a quiet operating blower of minimum capacity that can be used during prolonged periods of silent running. | ||

| The supply and exhaust lines have a gate stop valve at each bulkhead. Reach rods pass through the bulkhead to provide operation from either side. This type of valve provides less resistance to flow than the double-seated valve on U.S. submarines. However, it is not quick closing in its present design and does not have the advantage of closing with pressure. | ||

| Provision for battery ventilation by the use of the main ventilation system is considered fully adequate. However, the technique of blower operation during battery charging and discharging does not meet required U.S. standards. This has been fully discussed in the NavTech Report No. 310-45, "German Submarine Battery Installation and Battery Ventilation". The air flow meters are not as conveniently located in the maneuvering room as on U.S. submarines, thereby requiring additional or roving personnel to witness both air flow and charging rates. | ||

| The air purification and oxygen renewal systems are based on the requirements of 44 men during 72 hours total submergence. For air purification, a total of 315 canisters, each | ||

- 3 - |

||

9C-S38 |

||||||||||||||||||||||||||

| capable of absorbing 400 liters of CO2, are provided. For oxygen renewal a total of 13 flasks, each containing 50 liters of oxygen under 160 atmospheres (2275 p.s.i.) pressure, are installed. 44 sets of emergency breathing apparatus are carried on board. | ||||||||||||||||||||||||||

| 4. NOTEWORTHY CHARACTERISTICS | ||||||||||||||||||||||||||

| The ventilation system provides an interesting design study. Duct diameters for the main supply and exhaust lines are appreciably smaller than those used in U.S. design. Wall thickness, however, is much greater (approx. 3/16"). German submarine specifications allow higher maximum duct velocities (approx. 4000 F.P.M.) than in U.S. practice (2500 F.P.M.). This permits the use of smaller duct sizes but increases the static drop along the line. As a result, the blowers used are designed to provide a high static head. In order to produce the required capacity, the power ratings of the blower and its prime mover are comparatively high. The characteristics of the U.S. and German blowers are listed below: | ||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

| The increase in blower revolutions decreases the overall size of both the blower and its motor. They occupy essentially the same volume and weigh approximately the same as the U.S. supply blower and its motor. The German blower, because it requires a greater power and higher speeds for similar capacities, has a greater effect on fuel consumption and appears to be somewhat noisier on shipboard tests. Underwater sound tests have not been conducted, so at this time no true sound comparison can be made. | ||||||||||||||||||||||||||

| The advantages to be gained from use of smaller duct sizes are worthy of further discussion. A material overall saving in space is achieved. The increase in space for the larger blower is local and is over-balanced by the decrease brought about by the use of small main supply and exhaust ducts and fittings throughout the vessel. Better internal arrangements can be provided as a result. With this decrease in space requirement is also a corresponding decrease in overall weight. The major weight saving is from the decreased size of bulkhead valves and associated operating gear which at present constituted a greater percentage of the weight then the remaining | ||||||||||||||||||||||||||

- 4 - |

||||||||||||||||||||||||||

9C-S38 |

||

| pipes and fittings in the system. | ||

| 5. CONCLUSIONS | ||

| The ventilation system installed is adequate for both ship and battery ventilation. Its flexibility and wide capacity range make it suitable for operation under most normal, emergency or silent running conditions. The general layout, however, is believed inferior to that on recent U.S. submarines. | ||

| The air purification and oxygen renewal systems, while adequate by U.S. standards, are considered too elaborate in their details. The lack of means for conditioning the air is a decided weakness in the vessel's design. | ||

| 6. RECOMMENDATIONS | ||

| It is recommended that a design study be made to determine what sacrifices are necessary in order to provide the present ventilation arrangement with materially smaller main duct sizes, using velocities comparable to those permitted in German submarine design. It is believed that the benefits gained would more than compensate for the added blower horsepower ratings and that the employment of recent sound reducing practices to blower, motor and vent duct design would reduce the higher sound levels obtained to acceptable levels. | ||

- 5 - |

||

|

|